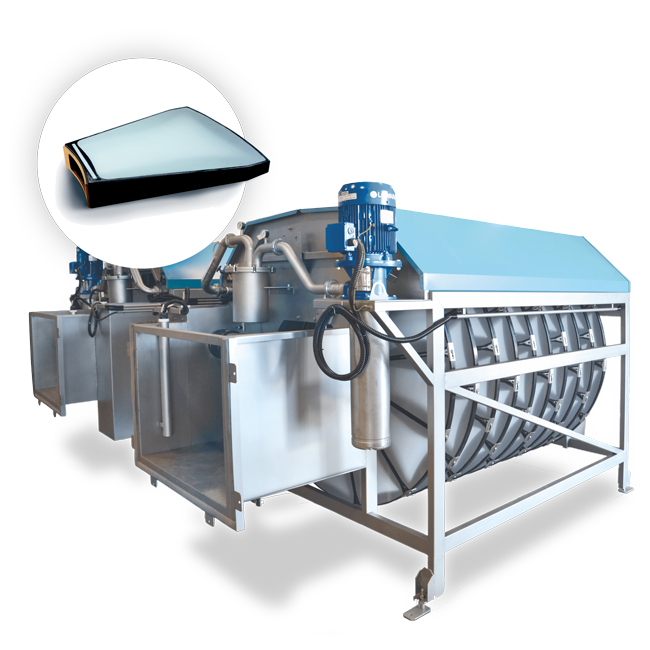

Disc filter

Disc filters are designed for tertiary treatment of municipal and industrial waste water.

The disc filter was developed by IN-EKO Team s.r.o. by applying all the acquired knowledge and twenty-year experience in water filtration systems.

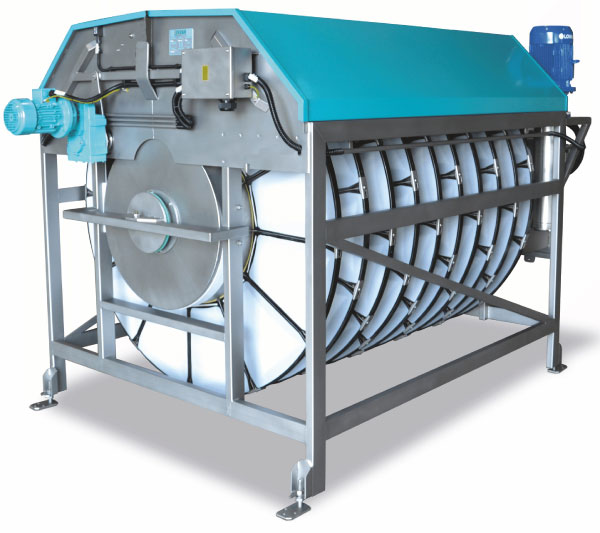

Disc filters can boast of an ideal proportion of filtration area and floor space.

How it works

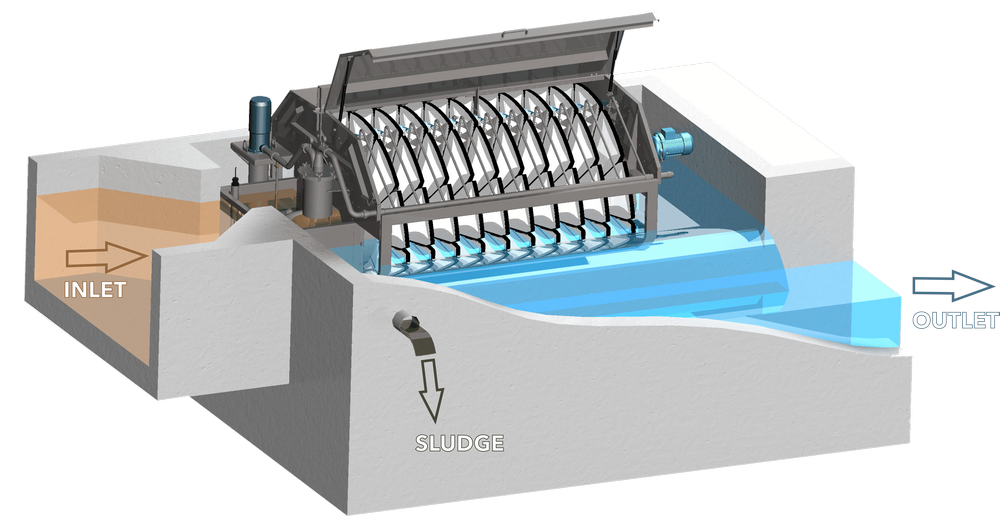

Waste water flows by gravity from the central drum through filtration segments. The filter drum is idle at the beginning of the filtration cycle – it does not rotate. Suspended solids get caught on the inner side of the segments covered by a filter cloth. As the cloth gradually becomes clogged with suspended solids, the water flow through the cloth decreases and water level inside the drum gradually increases. Water level probe activates the rotation of the filter discs and in the same time the backwash system is turned on.

High-pressure backwash rinses impurities off to the sludge manger. The water level inside the drum decreases, the flow is again at its peak with minimum water level. The filtration cycle repeats. Filtration proceeds continually without interruption.

Properties

Design and properties

of the disc filter

In order to ensure the highest possible standards in waste water treatment technology, only premium quality materials are used in production of our disc filters. Filter cloth with mesh opening between 5 – 200 μm. The difference of 100 – 150 mm in water levels enhances filter capacity (up to 500 l/s). The filter drum is suspended on kevlar belts.

Load applied to the shaft is reduced by a hollow frame of the segment which prolongs the life of all mechanical parts. Disc filters are equipped with abrasion resistant sealing of the drum. No bearings are immersed in water – this eliminates the risk of water contamination. Unique design of efficient rinsing nozzles.

IN → OUT

System

This well-proven system ensures the highest possible filter efficiency. Water flows into the drum from where it is taken to individual segments. Suspended solids are caught inside the segment and treated water flows out.

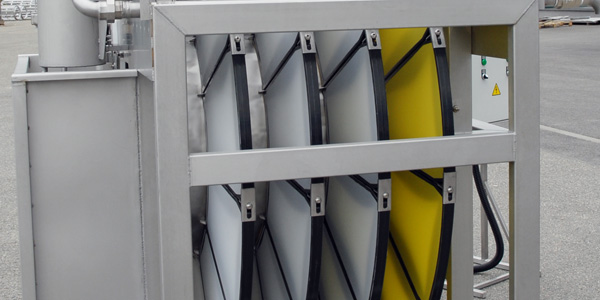

FILTRATION SEGMENTS ARE MADE OF RESISTANT PLASTIC ABS AND WELL-PROVEN FILTER CLOTH.

Advantages

for customers

Better quality of water flowing from the outlet

Big filtration area in a small floor space

Gravity flow saves energy costs

Exceptionally quick and easy replacement of filtration segments

Filters can be adjusted to suit customer’s requirements / project’s requirements

Recovery of precious materials back to the process saves initial costs.

Requires very little maintenance

After installation the unit is immediately ready for operation.

Contact

Trnec 1734

666 03 Tišnov

IČO: 63478463

DIČ: CZ63478463

OR: KS Brno C/20649